S:Prout - Soft Tectonics 유연의 구축법

I.f CDL Research Pavilion

2024

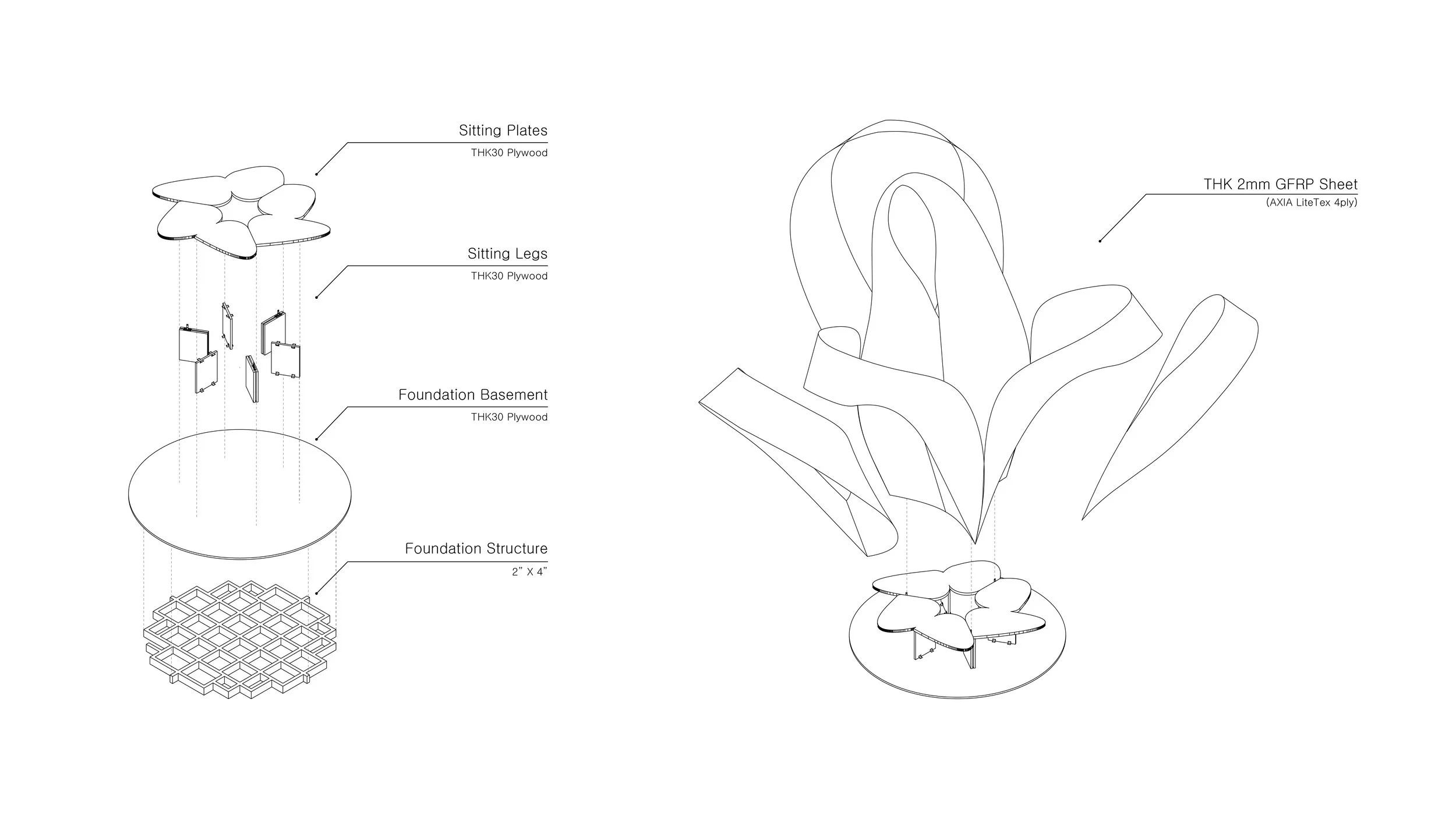

Architecture with Flexible Materials: Discovering New Possibilities

Flexible materials stimulate architectural creativity through their inherent physical properties and capacity for transformation. In traditional vernacular architecture, materials such as bamboo and earth have been utilized to create adaptive, flexible structures that respond to local environmental conditions and needs. Contemporary architecture reinterprets this flexibility by experimenting with high-performance composite materials. LiteTex, the material used in this project, is a continuous fiber composite that begins as a flat sheet and holds potential for transformation into three-dimensional forms. This material simultaneously offers elasticity and rigidity, maximizing portability and storage while enabling the creation of complex structures on-site. By applying two-dimensional patterning techniques from the garment industry, this approach enables the transformation of flexible, flat materials into three-dimensional forms, simplifying the fabrication process and ensuring cost-effectiveness. LiteTex represents more than a material experiment; it expands the possibilities of architectural design. This material is not only suitable for spatial requirements such as movable structures, temporary buildings, and pavilions, but it is also recognized for its environmental sustainability.

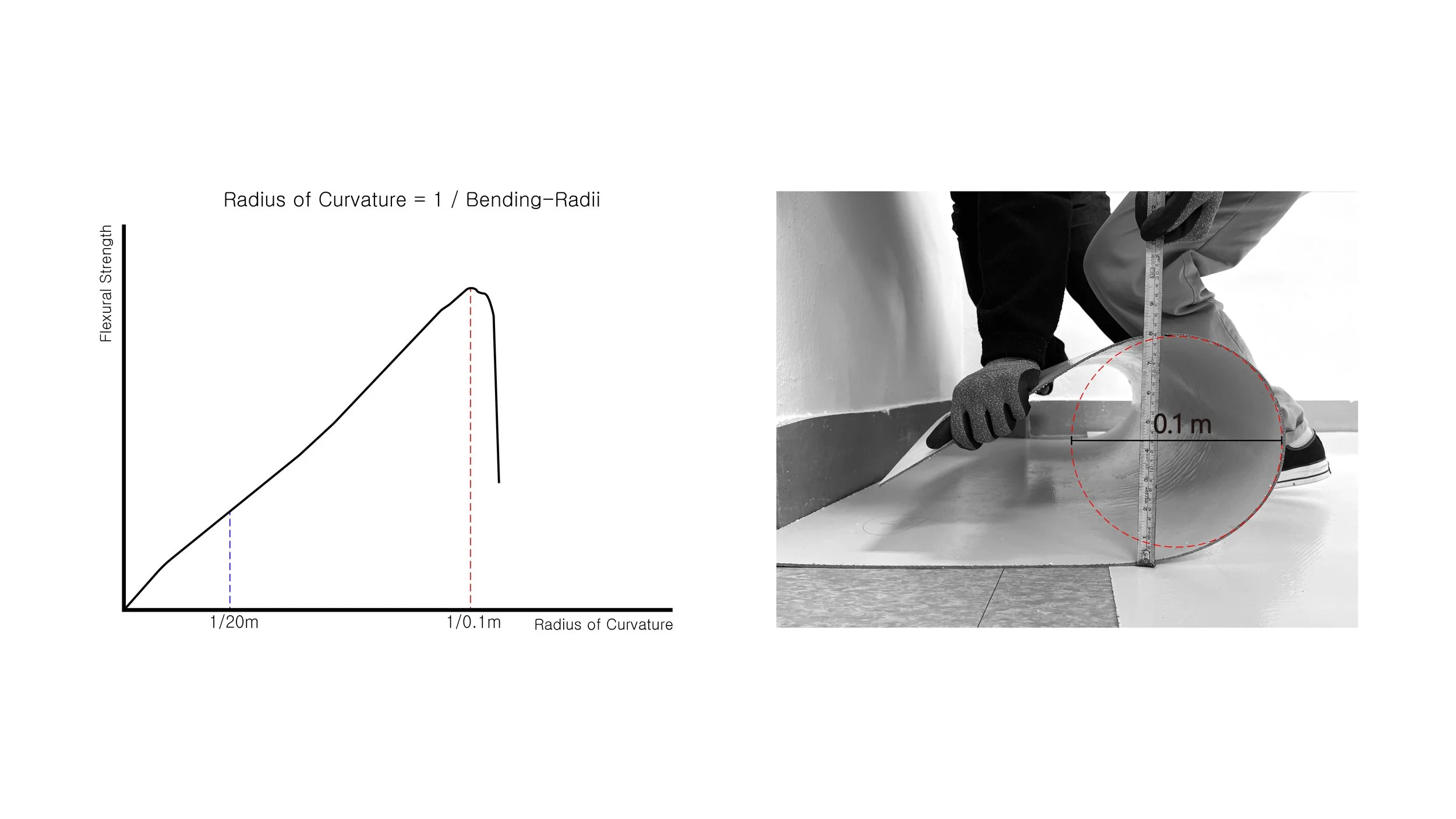

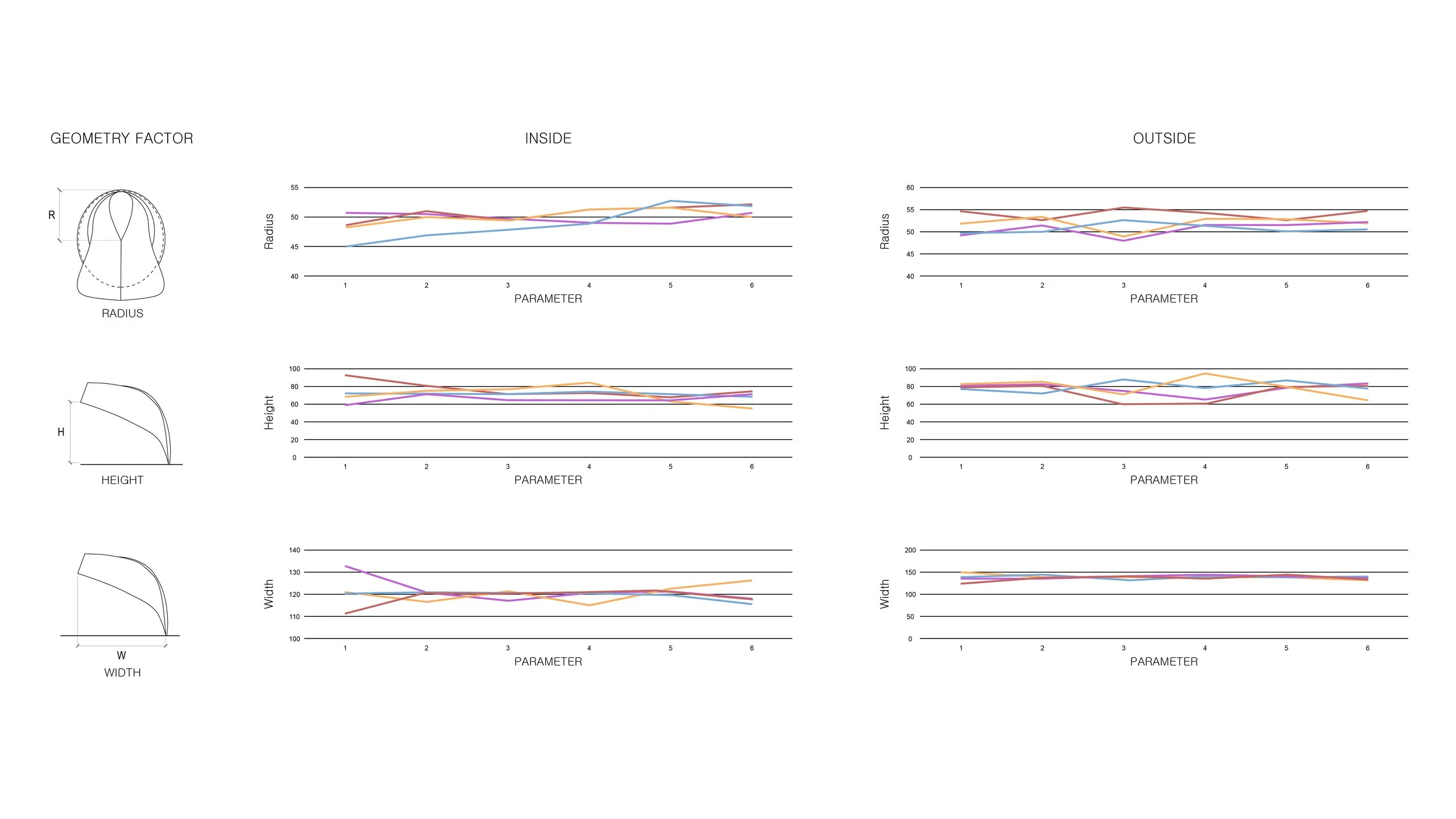

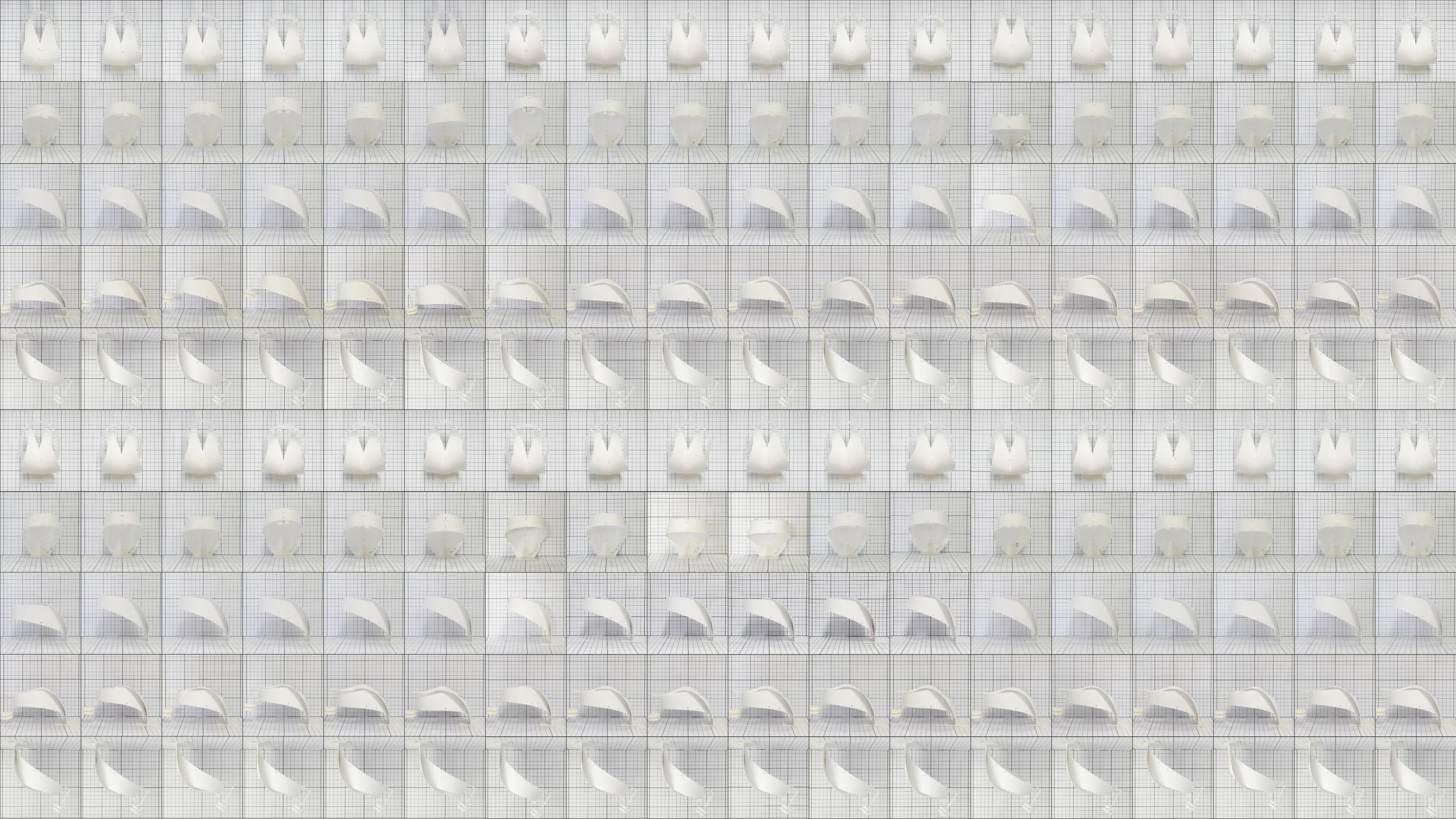

Designing Change: Process-Oriented Design and Fabrication

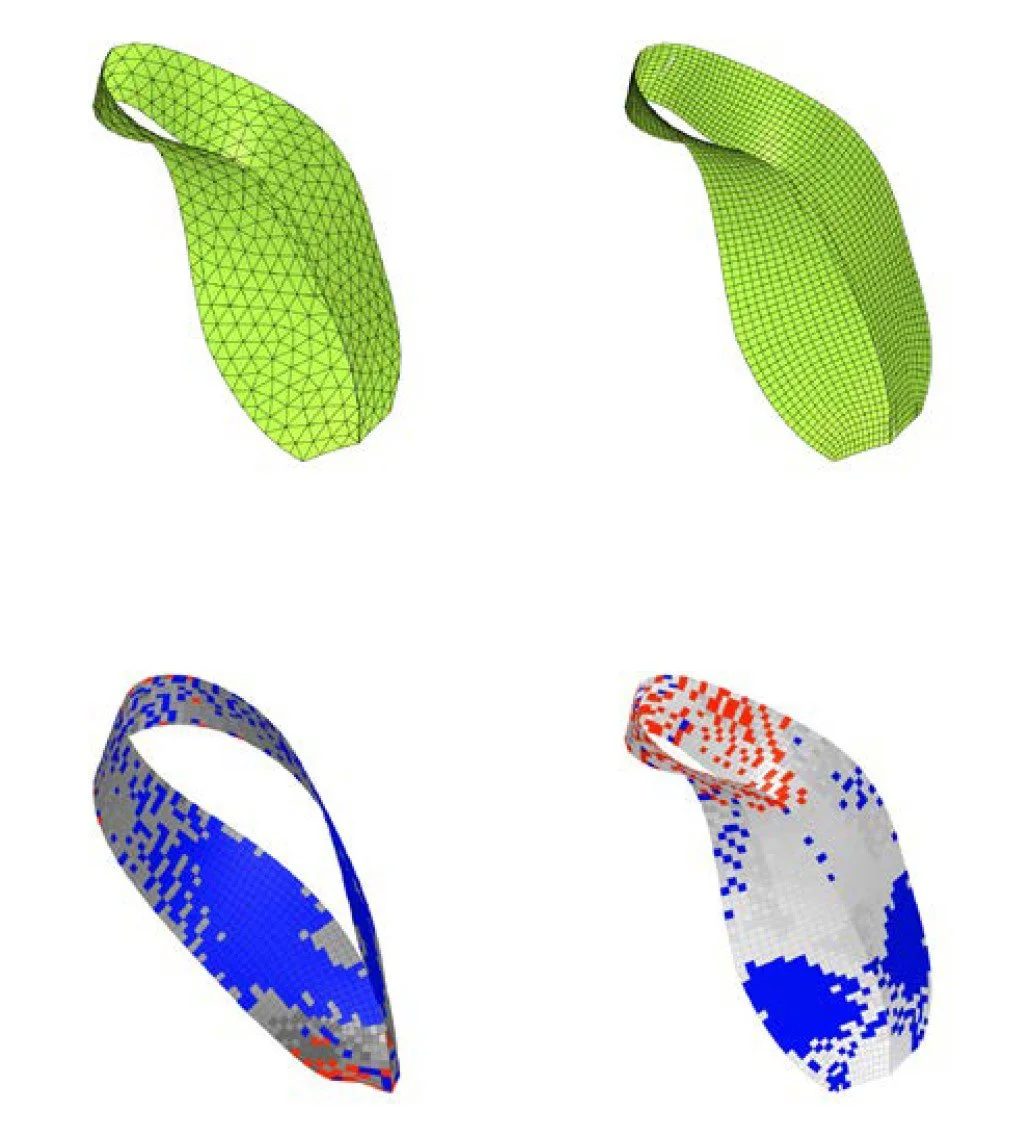

Designing change involves more than the creation of a final product; it requires the integration of the entire process by which that product is realized. This project focuses on the research of the design and fabrication process, investigating the physical properties and limitations of flexible materials through the integration of digital technologies and physical experimentation. The design process is divided into three distinct phases. The first phase involves basic form experiments using scale models to analyze the relationships between the material’s physical properties and the design variables. The second phase combines digital simulations with physical testing to assess the material’s behavior in real-world conditions. Finally, full-scale mock-ups are constructed to identify potential issues in the assembly process and derive solutions. By considering factors such as the material’s bending radius, self-weight, and assembly sequence from the early design stages, it is possible to achieve not only three-dimensional forms but also structural stability and spatial efficiency. This approach enhances the overall quality of the final product while minimizing errors during fabrication.

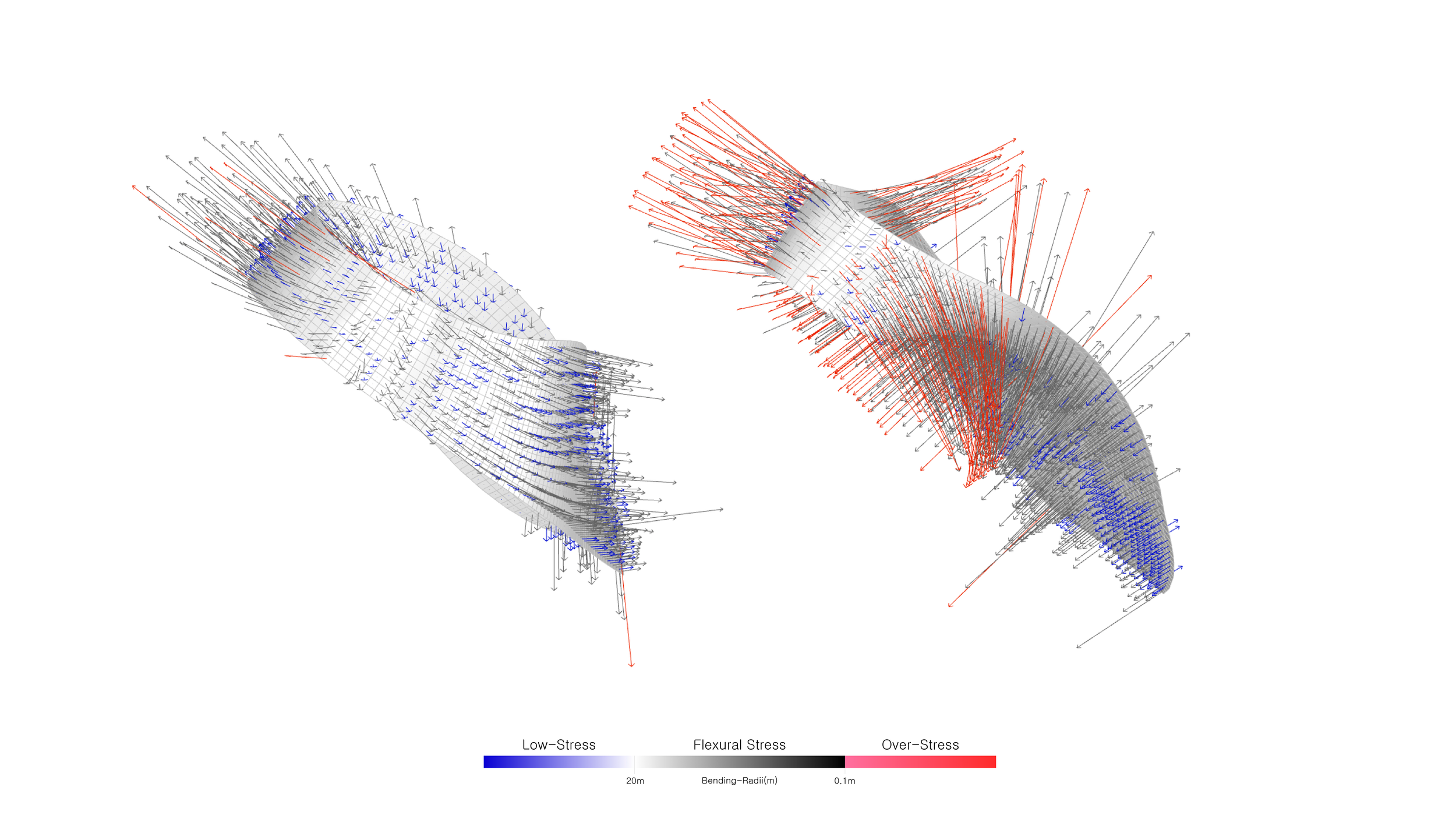

Integration with Digital Technology: Employing New Design Tools

Digital technology plays an essential role in effectively integrating the design and fabrication processes. In this project, a digital twin was constructed to measure the gap between the virtual model and physical reality, allowing for simulations of changes throughout the entire design and fabrication phases. Digital simulations were utilized as a tool to validate the design’s efficiency before creating physical mockups. Factors such as bending strength and deformation limits were analyzed in advance, enabling the identification of potential errors prior to fabrication. These simulations facilitated collaboration among architects, engineers, and material specialists, and helped integrate data from multiple disciplines. Physical experiments served to verify the outcomes of digital designs and test the performance and assembly feasibility of the materials. The complementary relationship between digital simulations and physical testing improved the reliability of the design and further extended the potential of new materials and technologies.

Project Team : I.f Convergence Design Lab + Center for Ai & Architecture (Ai+A)

(Prof. Dongil Kim)

Principal Researcher : Seungil Kim, Gwangeun Hwang

(Scientific / System Development, Fabrication and Construction)

Project Assistant : Dongheon Lee, Jinsan Ryu, Isaac Kang, Yeonhee Kim, Hyeongtai Kim, Ro-un Yi (DAKHU)

With the Support of : Seojoo Lee, Hyojung Kim (I.f)

Taejung Kim (KOLON GLOBAL), Taehun Kim, Minjun Kim (AXIA)

Junghwan Koo (EFFECTOR)

Daehan Lee (V.P.Lab), Teahyun Kim (DAKHU)

Supported by : I.f Architecture&Research, AXIA Materials, Kolon Global

Dept. of Architecture Kyung Hee University, Kyung Hee Univ. Convergence Technology Research Institute

EFFECTOR

Photography : Kyung Roh